TIJ Thermal Inkjet Printers: Weighing the Pros and Cons

Whether you're looking for an inkjet address printer or need a versatile direct package inkjet printer, understanding TIJ technology is crucial. These printers utilize heat to create vapor bubbles that force ink through tiny nozzles, resulting in precise prints on various materials.

The Advantages of TIJ Printers

TIJ printers deliver impressive resolution up to 600 DPI, making them perfect for detailed address printing, many barcodes, and even logos. If you need crisp, professional-looking output, these printers rarely fail to deliver.

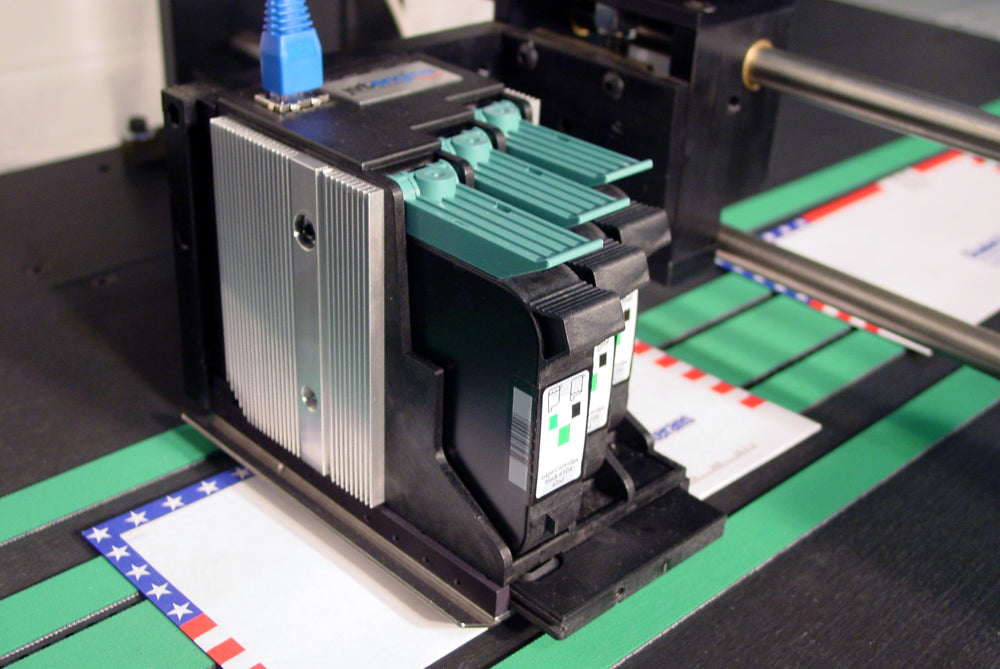

Here's where TIJ really shines. With fewer moving parts than other industrial inkjet printers, they're surprisingly easy to operate. The cartridge system is straightforward – when you replace a cartridge, you get a fresh print head too, eliminating separate maintenance headaches.

Less maintenance means more uptime. TIJ printers don't require the constant attention that some other printing technologies demand. No makeup fluids, no complex print systems – just reliable printing day after day.

The initial investment for a thermal inkjet printer is typically lower than that of continuous or drop-on-demand inkjet alternatives. This makes them attractive for businesses testing the waters with automated addressing, package printing, or those with budget constraints.

Many TIJ printers use water-based inks, generating less hazardous waste compared to solvent-based systems. They also consume less energy, which is good for both your operating costs and environmental footprint.

Need to get up and running fast? TIJ printers seamlessly integrate into existing production lines and work effectively with various document feeders and conveyor systems.

The Drawbacks to Consider

While the initial purchase price is attractive, replacement cartridges can be pricey. This is especially noticeable in high-volume operations, where cartridges are used regularly.

TIJ printers work best on absorbent materials like paper and cardboard. If you're printing on plastics, metals, or other non-absorbent surfaces, you may need specialized inks or might find the results less than ideal.

Each TIJ print head has a print height of 0.5" to 1.0". While you can combine multiple heads for larger areas, this adds complexity and increases the cost of your setup.

When you need to print images larger than a single cartridge can handle, multiple inkjet cartridges must be precisely "stitched" together. For example, creating a 2" high image requires careful alignment of several cartridges. If the stitching isn't perfect, you'll end up with jagged borders or unsightly white spaces between cartridge coverage areas – not the professional look you're aiming for.

In demanding, high-speed applications, TIJ printers may not keep up with continuous and drop-on-demand inkjet systems. If you're running thousands of pieces per hour, this could be a limiting factor.

The heat-based technology restricts available ink types and colors. If you need specialty inks or a broad color palette, you might find your options somewhat limited.

Making the Right Choice

TIJ printers offer an excellent balance of quality, ease of use, and reasonable operating costs. They're particularly well-suited for businesses that prioritize print quality and operational simplicity over maximum speed.

Consider a thermal inkjet printer if you're printing primarily on paper-based materials, need high-quality output, and value low-maintenance operation. They work exceptionally well with friction feeders and standard document feeders for automated addressing and packaging applications.

However, if you're dealing with non-absorbent materials, require very high-speed printing, or need specialty inks, you may want to explore other industrial inkjet printer options.

The key is matching the technology to your specific needs. What matters most in your operation – print quality, speed, material compatibility, or operating costs? Your answer will guide you to the right choice.

Need help choosing the right inkjet technology for your application? Contact us at 314-209-7272 or send an email to info@peak.bz