Friction Feeders are among the most versatile product feeders on the market today. You'll find them in many places, including:

- Commercial Printers

- Direct Mail Companies

- Packaging and Fulfillment

- Manufacturers

Typical uses include feeding flat products such as postcards, envelopes, cards, flat cartons, flat boxes, and marketing material into other equipment or packaging. While the friction feeder is an excellent choice for many products, alternative feeders exist and do a better job with some products, as described below.

Shuttle Feeders:

Shuttle Feeders use vacuum and pinch rollers to feed one product at a time into other equipment or onto an integrated conveyor belt. The bottom-feed technology allows continuous operation, so there isn't a need to stop and reload.

Cost: $8.5K - $15K

Setup Time: Varies from 2-10 minutes

Skill Level to Operate: Low to Medium

Best for Magazines, Newspapers, Booklets, Perfect Bound Books, Zippered Semi-Rigid Pouches, Semi-Rigid Bags, and Products up to 5/8" Thick.

The Shuttle Feeder isn't limited to thicker products and may also be used to feed envelopes, postcards, and other thinner materials typically fed with a friction feeder.

KR-324 Shuttle Feeder

KR-224 Shuttle Feeder (with an outfeed conveyor belt)

KR-215 Shuttle Feeder (with an integrated long conveyor belt)

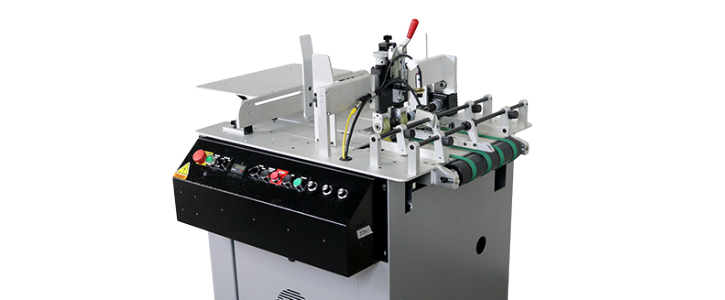

Vacuum Cup Feeders:

Vacuum Cup Feeders vary in size and are dependent on the product size. Almost all of them have a row of suction cups that pick and place a product from the top of a stack.

Costs: $7.5K - $45K

Setup Time: 5-10 minutes

Skill Level to Operate: Low to Medium

Best for bags, napkins, flat cardboard, coasters, and heavy, large and rigid products.

Vacuum Cup Feeders may include in-feed conveyors so non-stop production is possible. They may also have integrated conveyor belts for labeling or inkjet printing the products after feeding onto the conveyor belt.

KR-725 Vacuum Cup Feeder (with an integrated conveyor belt)

Sheet Feeders:

Sheet Feeders typically pull paper and related products from the top of the stack using belts with or without vacuum assist. While non-stop operation isn't possible, loading a new stack takes less than a minute or two. You'll find sheet feeders integrated with printers and print-finishing equipment.

Costs: $18.5K and up

Setup Time: 5-10 minutes

Operator Skill Level: Low to Medium

Best for paper sheets and other similar products.

Sheet Feeders may include ultrasonic double feed detection or be optional. Either way, it's a must-have item that stops the machine if more than one product feeds at a time.

Need help selecting the best feeder for your application? We'd love to help.

Thanks!

Greg Polk at (314) 209-7272 or gpolk @ peakbe dot com